The focus of your business is making components, and while reliable inspection is an important part of manufacturing, it’s not your core focus. Unfortunately, that means that while you’re focused on the latest technology and expert staff for production, you may lag behind when it comes to inspection. Problems with inspection or a lack of equipment or staff can just as easily result in bottlenecks as a problem on the shop floor. For many shops, contracting metrology services is easier and more affordable than making a big investment in new measuring instruments and staff.

Contract Coordinate Measuring Machine Inspection

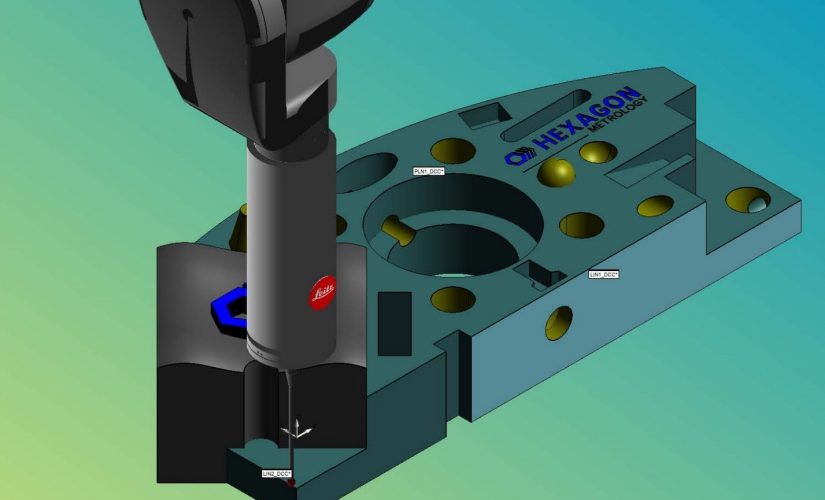

Does your shop lack the tools, the operators, the expertise, or the time to inspect a new line of components? You have two options for outsourcing your parts inspection: in-house contractors and in-lab inspection. In-house contractors come to your shop to inspect components, and they may use either your coordinate measuring machines or bring their own, like a portable arm.

The in-lab option means sending components to a metrology contractor; while it can get expensive transporting them to the lab, it’s a better solution for measurements that need a high degree of accuracy. Contract metrology houses like the company Canadian Measurement Metrology use the newest equipment and software to quickly deliver highly accurate data.

CMM Programming

CMM programming is how you tell a coordinate measuring machine where to measure and how, i.e., either by point contact or dragging. Software from several years ago lags far behind the capabilities of CNC software, and older software is less user-friendly and comes with fewer features. Using cumbersome software adds hours to the process of CMM programming, while software that does not allow you to program from CAD can lead to even further bottlenecks, as it will require a finished component from which to program the inspection routine. That inevitably creates a bottleneck, as you have to first program the inspection routine before you can inspect finished components.

New software programs such as PC-DMIS 2017 can drastically reduce the amount of time your programmers spend to create a new routine. However, you can also contract CMM programming services from an independent metrology dealer. It’s a great solution if you don’t have the trained staff to quickly program a new parts routine or your staff is tied up on other projects. Application engineers at the metrology company Canadian Measurement Metrology regularly support shops with offline programming, program modifications, product launch support, and software update training. You can also rely on contract CMM programming to write programs for any number of tasks, including components with complex geometries, gears, blades, and guided routes for portable arms and laser trackers.

Contract solutions for both inspection and CMM programming can help you avoid bottlenecks and keep everything running smoothly. Your metrology department needs to keep up with component production if you’re going to reliably meet your deadlines. A contract metrology company that uses the latest equipment and programmers who know software inside and out can get you back on track. If your shop is overwhelmed by complex programming demands, get outside help.

Leave a Reply